3/8 inch Galvanized guy wire as per ASTM A 475 Class A EHS

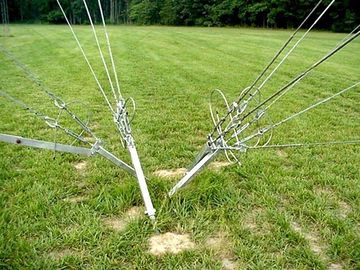

Whether you have heard it called guy strand, guy wire or guide wire, these normally refer to 1x7 Extra High Strength (EHS) galvanized strand cable. Designed with very little stretch and flexibility this cable is generally used to reinforce and add stability to tall structures; reinforcing everything from radio towers to wind turbines and is ideal for bracing and tensioning applications for arborists’ and linemen.

Our Guy Wire is Class A galvanized, meets ASTM A-475 specifications, is independent lab verified and quality assured.

| Mechanical and Technological Properties of Galvanized Steel Strand | |||||||||

| Struct | Dia(mm) | Dia Stand(mm) | Dia Stand(mm²) | Tensile Strength(Mpa) | Weight(kg/100m) | ||||

| 1270 | 1370 | 1470 | 1570 | 1670 | |||||

| Minimum Breaking Force(KN) | |||||||||

| 2.90 | 6.20 | 19.82 | 23.10 | 24.90 | 26.80 | 28.60 | 30.45 | 15.99 |

| 3.20 | 6.40 | 24.13 | 28.10 | 30.40 | 32.60 | 34.80 | 37.07 | 19.47 | |

| 3.50 | 7.50 | 28.86 | 33.70 | 36.30 | 39.00 | 41.60 | 44.34 | 23.29 | |

| 4.00 | 8.60 | 37.70 | 44.00 | 47.50 | 50.90 | 54.40 | 57.92 | 30.42 | |

| 1.00 | 3.00 | 5.50 | 6.43 | 6.93 | 7.44 | 7.94 | 8.45 | 4.37 |

| 1.20 | 3.60 | 7.92 | 9.25 | 9.98 | 10.71 | 11.44 | 12.17 | 6.29 | |

| 1.40 | 4.20 | 10.78 | 12.60 | 13.59 | 14.58 | 15.57 | 16.56 | 8.56 | |

| 1.60 | 4.80 | 14.07 | 16.44 | 17.73 | 19.03 | 20.32 | 21.62 | 11.17 | |

| 1.80 | 5.40 | 17.81 | 20.81 | 22.45 | 24.09 | 25.72 | 27.36 | 14.14 | |

| 2.00 | 6.00 | 21.99 | 25.69 | 27.72 | 29.74 | 31.76 | 33.79 | 17.46 | |

| 2.20 | 6.60 | 26.61 | 31.10 | 33.55 | 36.00 | 38.45 | 40.88 | 21.00 | |

| 2.60 | 7.80 | 37.17 | 43.43 | 46.85 | 50.27 | 53.69 | 57.11 | 29.51 | |

| 3.00 | 9.00 | 49.50 | 57.86 | 62.42 | 66.98 | 71.54 | 76.05 | 41.19 | |

| 3.20 | 9.60 | 56.30 | 65.78 | 70.96 | 76.14 | 81.32 | 86.50 | 44.7 | |

| 3.50 | 10.50 | 67.35 | 78.69 | 84.89 | 91.08 | 97.28 | 103.48 | 53.48 | |

| 3.80 | 11.40 | 79.39 | 92.76 | 100.10 | 107.40 | 114.70 | 121.97 | 63.04 | |

| 4.00 | 12.00 | 87.96 | 102.80 | 110.90 | 119.00 | 127.00 | 135.14 | 69.84 | |

| 1.60 | 8.00 | 38.20 | 43.66 | 47.10 | 50.54 | 53.98 | 57.41 | 30.4 |

| 2.00 | 10.00 | 59.69 | 68.23 | 73.60 | 78.97 | 84.34 | 89.71 | 47.51 | |

| 2.60 | 13.00 | 100.90 | 115.30 | 124.40 | 133.50 | 142.60 | 151.65 | 80.30 | |

| 4.00 | 20.00 | 238.80 | 272.90 | 294.40 | 315.90 | 337.40 | 358.92 | 190.05 | |

| 1.60 | 11.20 | 74.39 | 80.30 | 86.63 | 92.95 | 99.27 | 105.60 | 59.50 |

| 2.00 | 14.00 | 116.20 | 125.40 | 135.30 | 145.20 | 155.10 | 164.95 | 93.00 | |

| 3.20 | 22.40 | 297.60 | 321.30 | 346.60 | 371.90 | 397.10 | 422.44 | 238.00 | |

| 4.00 | 28.00 | 465.00 | 52.00 | 541.50 | 581.00 | 620.50 | 660.07 | 372.00 | |

| Physical Properties of Zinc Coated Steel Wires Strand(ASTM A475) | |||||||||

| Nominal diameter of Strand. In (mm) | Number of Wires in Strand | Nominal diameter of Coated Wires in Strand. (mm) | Approximate Weight of Strand(kg/304.8m) | Minimum Breaking Strength of Strand (KN) | |||||

| Utilities Grade | Common Grade | Siemens Martin Grade | High Strength Grade | Extra High Strength Grade | |||||

| 3/16 (4.76) | 7 | 1.57 | 33 | ----- | 5.115 | 8.452 | 12.677 | 17.748 | |

| 7/32 (5.56) | 3 | 2.64 | 40 | ----- | 6.228 | 10.409 | 15.569 | 21.796 | |

| 7/32 (5.56) | 7 | 1.83 | 44 | ------ | 6.850 | 11.387 | 17.126 | 24.020 | |

| 1/4 (6.35) | 7 | 2.03 | 55 | ------ | 8.452 | 14.012 | 21.129 | 29.581 | |

| 9/32 (7.14) | 7 | 2.36 | 74 | 20.462 | 11.432 | 18.905 | 28.469 | 39.812 | |

| 5/16 (7.94) | 7 | 2.64 | 93 | ----- | 14.234 | 23.798 | 35.586 | 49.820 | |

| 3/8 (9.52) | 7 | 3.05 | 124 | 51.155 | 18.905 | 30.915 | 48.040 | 68.503 | |

| 7/16 (11.11) | 7 | 3.68 | 181 | 80.068 | 25.355 | 41.591 | 64.499 | 92.523 | |

| 1/2 (12.70) | 7 | 4.19 | 234 | 111.206 | 32.917 | 53.823 | 83.627 | 119.657 | |

| 1/2 (12.70) | 19 | 2.54 | 229 | ------ | 33.895 | 56.492 | 84.961 | 118.768 | |

| 9/16 (14.29) | 19 | 2.87 | 289 | ------- | 42.881 | 71.616 | 107.202 | 149.905 | |

| 5/8 (15.88) | 19 | 3.18 | 361 | ------- | 48.930 | 80.513 | 124.995 | 178.819 | |

| 3/4 (19.05) | 19 | 3.81 | 524 | ------- | 71.172 | 116.643 | 181.487 | 259.331 | |

| Nominal Diameters and Minimum Weights of Coating for Zinc-Coated Steel Wires | |||||||||||||||||||

| Diameter(mm) | 1.57 | 1.65 | 1.83 | 2.03 | 2.36 | 2.54 | 2.64 | 2.77 | 3.05 | 3.18 | 3.30 | 3.63 | 3.68 | 3.81 | 4.09 | 4.19 | 4.50 | 4.55 | |

| Zinc Coated(g/m²) | 153 | 153 | 153 | 183 | 214 | 214 | 244 | 244 | 259 | 259 | 259 | 275 | 275 | 275 | 275 | 275 | 275 | 275 | |